Design

The design of a modern internal combustion engine involves a complicated process defined by deep analysis of all components that constitute it, with a great attention to those object parts highly stressed.

The main target of the major engine manufacturer is to reduce design and development time before starting with series production, in order to optimize and limit investment cost.

Duraldur S.p.A. faces this issue by using the most advanced technologies offered by the market, supported by the multi-year experience gained on field.

Continuous improving research and strength basis: this is what Duraldur can offer to his customer, in order to satisfy highest demanding.

The development of a new product, from its initial concept to sample production, goes through many essential phases by using the following technologies:

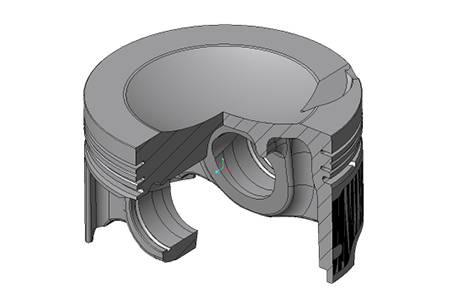

- ThinkDesign: Computer Aided Design (CAD) software to define component 2D/3D

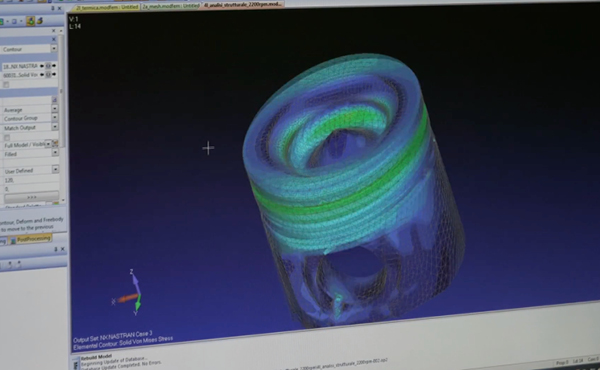

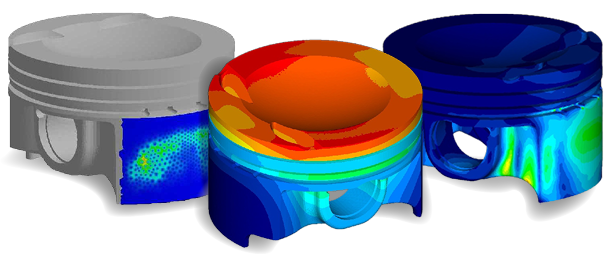

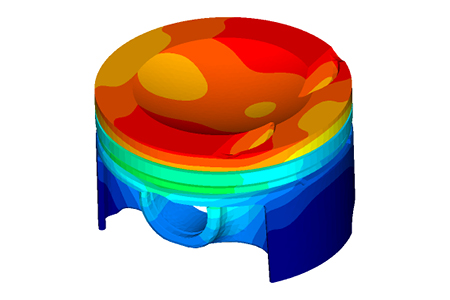

- Femap With NXNAstran: SIEMENS Product Lifecycle Management (PLM) software to perform Finite Element Analysis (FEA analysis)

- WinLIFE: STZ-Verkehr Product Lifecycle Management (PLM) software fully integrated with Femap used to perform durability analysis of designed component;

- Fearce & Pisdyn: Ricardo Product Lifecycle Management (PLM) software that allows to simulate complete piston dynamic during engine running.

(http://ricardo.com/en-GB/What-we-do/Software/Ricardo-Software-News/)

Numerical simulation nowadays is a fundamental step for the development of a new component and Duraldur S.p.A. takes great attention to new technologies that market offers.

Year by year considerable investments in every field allow our expert team a fruitful and constant improvement, in order to go on with the progress together with our customers that decides to trust in our competences.